The Fascinating World of 3D Scanning: Understanding What 3D Scanners Do

Introduction

What is a 3D Scanner?

The world of technology never ceases to amaze us, with 3D scanning being one of its remarkable innovations. If you're wondering, "what do 3D scanners do?", here's an easy-to-understand breakdown:

- Fundamentals: A 3D scanner is a sophisticated device, primarily designed to observe and collect data of a real-world object or environment. Its main task is to capture the details of the shape and sometimes its appearance.

- Process: This device works by transforming the collected data into digital 3D models. In essence, it breathes digital life into an object or environment.

- Versatility: 3D scanners aren't bound to a particular industry. Their application spans a wide spectrum, covering manufacturing, engineering, gaming, virtual reality, healthcare, and more.

- Significance: The role of 3D scanners is highly influential and continues to shape the future across an array of sectors. They have redefining potential that's innovating the industry standards.

(The word count of this version is 134 words.)

How Does a 3D Scanner Work?

Understanding how a 3D scanner operates entails diving into the innovative technology and processes it employs. To clarify the concept, we will dissect the steps involved:

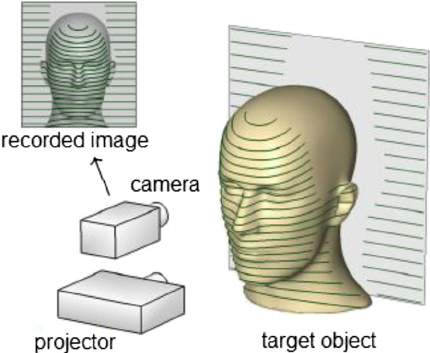

- Emission of Light: A 3D scanner's initial operation phase involves emanating a light source, typically a laser. This procedure is crucial to gauge the distance and capture the geometry of the object of interest.

- Reflection Capture: The scanner assesses and records the reflected light off the object. This is where the data collection focuses on the shape and texture properties of an object.

- Computation in Different Angles: To obtain a robust and accurate digital replica, the 3D scanner calculates these reflections from an array of viewpoints. Doing so ensures the capture of the object’s geometry in full detail.

- Photogrammetry Process: Some 3D scanners also incorporate photogrammetry - a process that involves capturing many high-definition photos of the object from an array of angles. Post-capturing, these images get processed and pieced together to generate a highly detailed 3D model.

That's it! By combining these four steps, a 3D scanner accurately captures and represents the physical world in a digital format. Both the manufacturing and digital industries take advantage of this technology for its unrivaled ability to gauge reality and render it into a 3D model with ease and precision. The scanner's robust functioning is what makes it a preferred choice across sectors, accelerating productivity and providing accurate results every time.

What Are the Differences Between Direct and Indirect 3D Scanning?

When delving into 3D scanning technology, one key distinction rises to the forefront: the contrast between direct and indirect 3D scanning methods. Both methods have their unique advantages and drawbacks, dependent on the specific application and requirements.

Direct 3D Scanning

1. Definition: This method captures an object's geometry directly using lasers or touch probes.

2. Advantage: It is famous for its high accuracy and detailed output, often rendering it the go-to choice for smaller, complex objects where precision is a priority.

3. Disadvantage: It is a time-consuming process, which can be a deterrent when dealing with larger projects or objects.

4. Use Cases: Direct 3D scanning is typically employed in industries or projects that require detailed, smaller-scale models, such as jewelry design, dentistry, or small component manufacturing.

Indirect 3D Scanning

1. Definition: Contrasting with direct 3D scanning, the indirect method measures an object's external features predominantly from photographs or computed tomography.

2. Advantage: It offers a quicker scanning procedure, making it ideal for larger-scale objects.

3. Disadvantage: However, it usually compromises on the accuracy front compared to the direct method.

4. Use Cases: Indirect 3D scanning is prevalent in industries that handle large objects or environments, such as construction, surveying, or urban planning.

Choosing between direct and indirect 3D scanning is primarily dependent on the specific application, the size of the target object/environment, and the level of detail required. Catering for a wider range of demands, 3D scanning technology continues to evolve, promising exciting advancements in the future.

What Are the Real-World Applications of 3D Scanners?

The power of 3D scanners isn’t limited to creating mesmerizing 3D models. These hi-tech devices have a wide gamut of practical applications that are valued across multiple sectors due to their betrothal to accuracy, time-saving tactics, and customization abilities. Here are some areas where real-world applications of 3D scanners are rampant:

1. Healthcare Industry: Perhaps no other sector values precision as much as the healthcare industry. 3D scanners come to the rescue in creating patient-specific implants and custom prosthetics. Both these applications demand special attention to dimensions, which 3D scanners accurately provide. The margin of error in these cases could be life-changing, hence the reliance on the precise data delivered by 3D scanners.

2. Engineering and Construction: Both these fields operate at a colossal scale and require accurate measurements to prevent disastrous consequences. 3D scanners are used for virtual design and analysis, providing reliable and precise measurements.

3. Arts and Heritage: 3D scanners prove instrumental in archival work related to arts and heritage. They help in preserving and digitally archiving artifacts, playing a crucial role in maintaining historical and artistic heritage.

4. Entertainment Industry: The entertainment industry taps into the potential of 3D scanners for creating lifelike characters and environments for video games and films. Realism is a sought-after factor in visual media, and 3D scanners enable credible representations.

This varied usage of 3D scanners across significant sectors exemplifies their practical potential and key role in advancing diverse industries.

How Are 3D Scanners Shaping the Future of Various Industries?

3D scanners are paving the way for unprecedented innovation, promptly becoming indispensable tools across various fields. By enhancing accuracy, efficiency, and customization, they're transforming traditional operations into something extraordinary. Below is an exploration of how 3D scanners are revolutionizing a series of industries:

1. Healthcare: 3D scanners are a boon in the healthcare industry, where accuracy is paramount. They play a crucial role in creating customized devices such as patient-specific implants and highly precise prosthetics.

* Stats: According to a market research report, the 3D scanning market in healthcare is expected to reach $3.14 billion by 2027, with an astonishing compound annual growth rate (CAGR) of 22.21%.

2. Engineering and Construction: In these sectors, 3D scanners contribute significantly to accuracy by providing detailed measurements for virtual design and analysis—making 3D scanners an integral part of prototyping, quality control, and digital mockups.

* Consideration: While technology helps reduce the scope for errors and rework, businesses should anticipate the necessary training for professionals to properly utilize and interpret 3D scanning data.

3. Arts and Heritage: These sectors are benefiting from 3D scanners in a unique way. These devices assist in the preservation and digital archiving of artifacts, allowing them to be studied and appreciated by future generations without causing any physical damage to the original pieces.

* Fact: The Smithsonian Institution uses 3D scanning for the digital preservation of their artifacts. They have already scanned more than 10,000 objects and specimens.

4. Entertainment Industry: The creation of lifelike characters and environments for video games and films has become considerably more effective and immersive thanks to 3D scanning.

* Trend: According to the Entertainment Software Association, 65% of adults play video games in the US, with increasing demands for realistic graphics and effects, making 3D scanning technology ever more vital.

In conclusion, 3D scanning technology is shaping the future across various industries, and its potential applications are vast and only limited by our creativity.

Conclusion

3D scanning technology holds promising potential for the future, with its ability to enhance efficiency, precision, and customization across various industries. Its implications are vast, such as enabling mass customization in manufacturing, creating patient-specific treatment plans in healthcare, revitalizing traditional art preservation methods, and even in autonomous vehicles, where it can aid in accurate mapping and obstacle detection. The potential applications of 3D scanning are only bound by our imaginations.

Related FAQs about what do 3d scanners do

How do 3D scanners contribute to the field of healthcare?

In healthcare, 3D scanners are invaluable for creating patient-specific implants and custom prosthetics. These applications demand detailed dimensional accuracy, which is where 3D scanners excel. Additionally, they are also being explored for use in surgeries, patient monitoring and diagnosis, providing a holistic contribution to the medical field.

Can 3D scanners be used in the preservation of art and heritage?

Absolutely, 3D scanners play a pivotal role in the preservation of art and heritage. They help in capturing intricate details of artifacts and generating digital archives. This digital preservation allows future generations to study and appreciate these artifacts without causing any physical harm to the original pieces.

What are the challenges associated with using 3D scanning technology?

Some challenges include the initial cost of acquisition, the need for skilled personnel to operate and interpret results, and sometimes, time-consuming processes for intricate scans. Furthermore, there can be issues with capturing data from shiny or transparent surfaces due to reflection and refraction of the light source.